How Cherry is Transforming Medical Device Training

The Cherry platform is useful for a lot of fun and flashy use cases. As a web-based 3D creation platform, it can be used to create immersive gaming experiences, as well as more radical software, from modeling product designs to creating a virtual shopping experience. But the Cherry platform supports more than just fun, design, and exploration – it also helps train health professionals on the latest medical devices.

Today we’re excited to share a new demo and case study highlighting our work in medical device training.

Medical Device Training: Opportunity for Transformation

The COVID-19 pandemic put additional stress on a system of medical device training that was already limited to on-hand, in-person sessions. People needed to be where the devices were to learn to use them.

At the same time, the new work-from-home reality ran the risk of slowing down important skills development during a global health crisis.

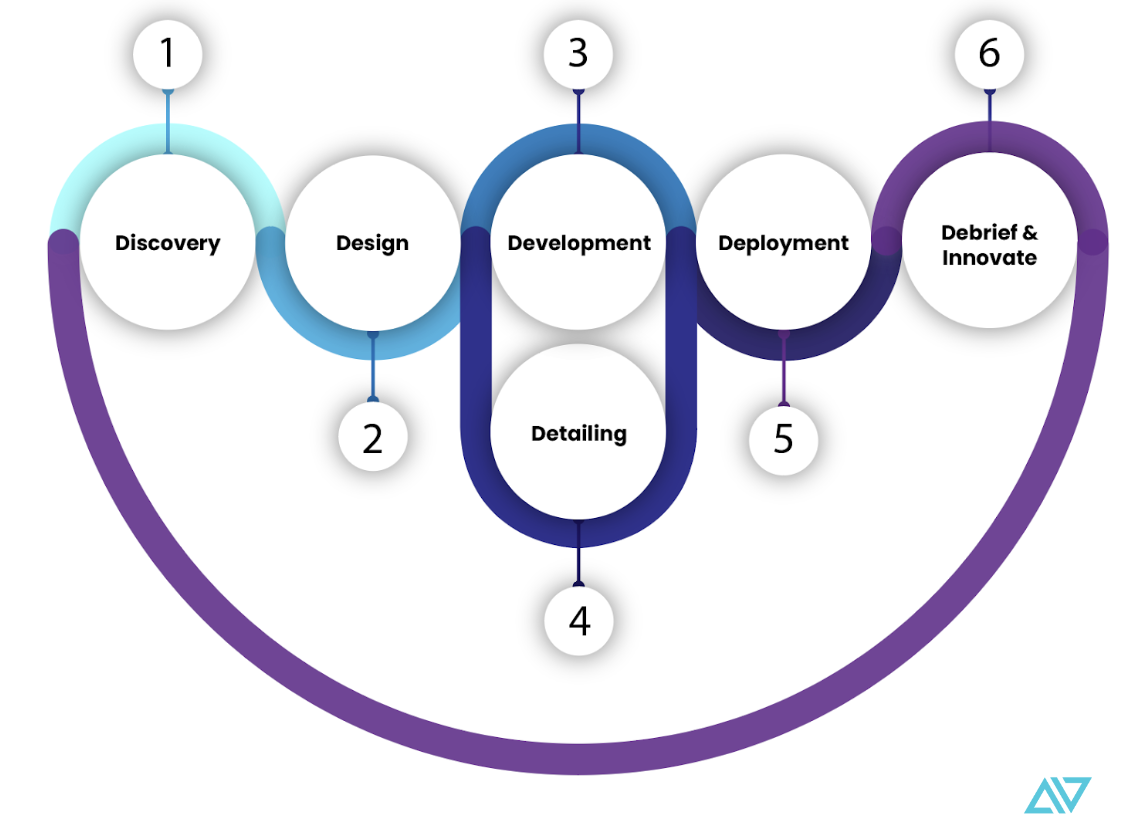

By delivering interactive 3D experiences over the web, the Cherry platform removes those location-based barriers, to make training modules in-engine with models as close to the real thing as possible. Now, we’re helping top medical device manufacturers develop such modules for their products.

But what does the Cherry platform actually do to make medical device training easier? Here are 7 ways interactive 3D experiences on the web are transforming the medical device training field.

1. Virtual Training Lets You Train Anywhere

Hands-on physical device training forces professionals to be physically near the machine. With virtual training, healthcare workers can learn anywhere, on any computer or mobile device.

2. Spatial Learning Improves Learning Outcomes

While remote training is usually done with text-based and video materials, these methods are two-dimensional. Immersive 3D modules bring the third dimension back into play, which better reinforces the material through spatial learning. Science backs this up – this study from the International Journal of STEM Education found that “using 3D models and animations in the teaching process significantly increased the students’ intrinsic motivation for learning natural sciences.”

3. Virtual Training Allows for More Training At Once

If you’re training on a real-world device, you can only fit so many people around it while demonstrating how to use it. (In some cases, only one person at a time!) A virtual 3D version of the same machine can be used by multiple people at once.

# 4. Gamification Encourages Learning

People are already accustomed to associating virtual experiences with gaming. Why not put that to good use as a motivational strategy? With digital badging and Continuing Education (CE), interactive 3D experiences increase engagement and retention by employing a scoring system, and reward trainees with achievements for reaching different degrees of proficiency in the training module.

5. Leveraging Existing Assets

Building fresh 3D assets can be a costly stage of development. But in most cases, the assets we use to create training modules don’t have to be made from scratch. Medical device manufacturers already have CAD files for their products developed during the design process, which can be easily re-purposed to build training modules.

6. Instant Updates for Real-Time Learning

When a new version of a device – or the software it runs on – is ready to roll out, people need to be trained on it right away. With our virtual medical device training modules, we can update all connected systems remotely and simultaneously. That keeps the entire workforce on the same page.

7. Reduced Travel and Labor Costs (and Smaller Environmental Footprint)

3D interactive experiences reduce the need for training professionals to travel, and reduce the overall carbon footprint. Training spatially on any computer takes the mileage out of the equation.

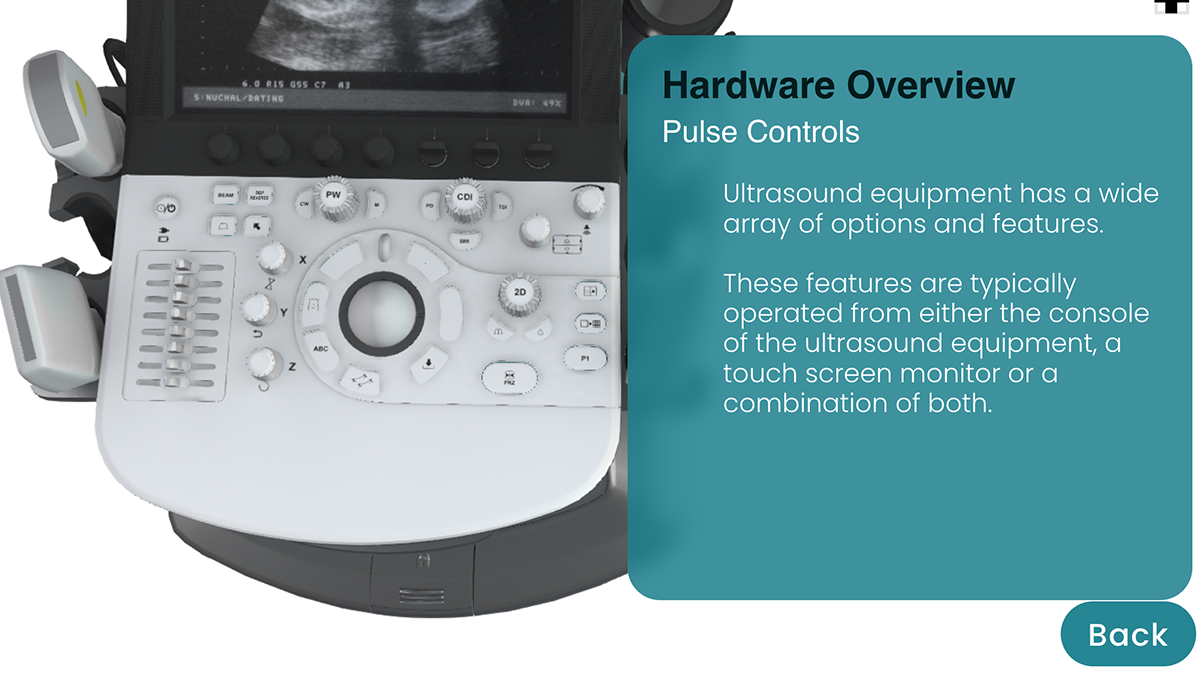

For more detailed information on our process, check out the new demo and case study below!

Creating immersive experiences is Cherry’s bread and butter, but we’re no experts when it comes to medical equipment. It’s been a learning process for us, creating training software for such precise medical equipment. Both for us, and our partners.

Creating immersive experiences is Cherry’s bread and butter, but we’re no experts when it comes to medical equipment. It’s been a learning process for us, creating training software for such precise medical equipment. Both for us, and our partners.

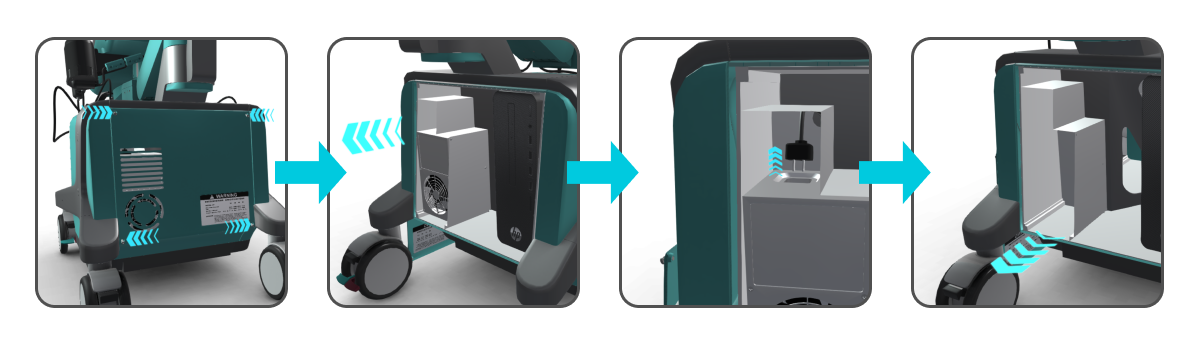

Translating materials from our partners, such as copious textual documents and supplemental video resources, into a three-dimensional experiential medium was challenging. But it’s worth it, as it makes for more intuitive training modules – ones that reinforce memory and learning, instead of relying on rote memorization.

Cherry works in tandem with our partners in the medical device field to achieve this outcome. We have the XR know-how, and our partners know the ins and outs of complex, finely-tuned medical equipment; combined, we have the necessary skills to create intuitive learning modules that don’t require a real-life machine to work from. To learn more about our process in-detail, check out our new demo and case study below.

We’re able to achieve this lofty goal by developing collaborative processes with our partners, who help us understand the machinery we’re simulating. We’ve even devised a “Step Guide” to outline the spatially translated procedures, instructions, and animations, and submit them for approval before they’re applied and timed in the 3D experience. This process is key to efficient development.

3D experience design is a lot like storyboarding a movie. Throughout the development process, we carefully walked through each step together with our partner, and gathered feedback from designers and training experts. Learn more in our case study “Cherry Immersive Training for Medical Devices.”

Thanks to this close collaboration with our partners in the medical device industry, the Cherry platform is transforming how people train on new healthcare technologies, something that will have a direct impact on the health of millions of people across the globe. We’ve been energized by this challenge as we make spatial learning easier across the medical device training field.